Mastering AAV production: best practices For small- to large-scale manufacturing success and reduced development time

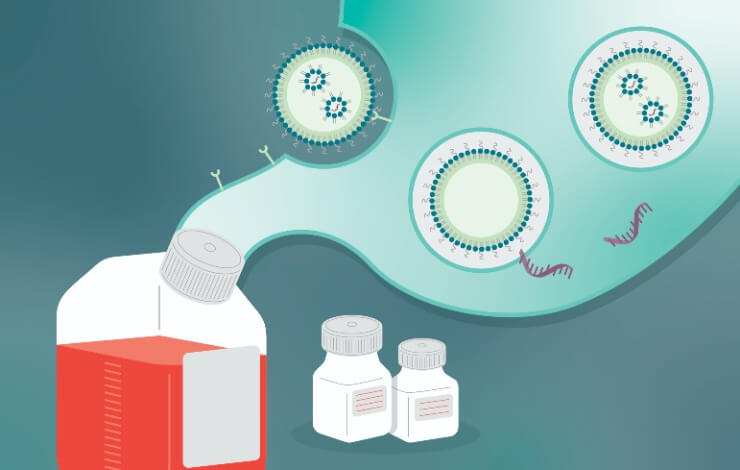

As AAV researchers and gene therapy developers optimize their AAV production process, key considerations are productivity, product quality, scalability, and cost. In this webinar, we will provide valuable insights and practical tips for AAV production at small-scale, including cell culture conditions, transfection protocols, and plasmid ratio optimization, which can reduce optimization time and help save precious development time and cost.

Additionally, we will highlight some key characterization and optimization studies our R&D team has done in order to enhance the scalable performance of the Gibco CTS AAV-MAX Helper-Free AAV Production System, as well as share use cases on scaling up into stirred-tank bioreactors, highlighting data at the 50L, 500L, and 1,000L scales.

Don’t miss this opportunity to stay ahead in the field of AAV production. Register now and join us for an engaging session with actionable strategies to elevate your AAV production and gene therapy development to new heights!

- Best practices for critical steps in the AAV workflow, including cell expansion and transfection

- How plasmid ratio optimization can improve productivity and percent full

- Process and protocol optimization to enable scalable production at 50-1000L

- How the CTS AAV-MAX system can address challenges in productivity, product quality, scalability, and cost

You have registered for this webinar

You might also like

Ensuring success in AAV scale-up: key data from case studies across four serotypes

Ensuring success in AAV scale-up: key data from case studies across four serotypes (APAC)

Navigating TFF in small-scale GMP: Insights for advanced therapeutics

Advancing AAV manufacturing: strategic insights and cost-effective solutions for the future of gene therapies