Discovery to manufacturing: A continuum

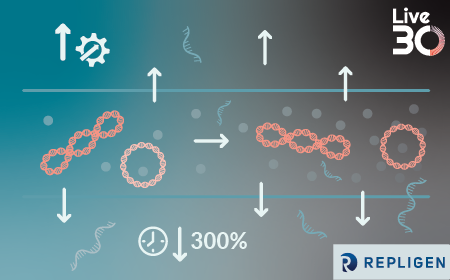

The design and development of new drugs should not be regarded as a series of discrete events, rather as a continuum of interdependent activities. This is very much the case for viral vectors, whether they are used as direct therapies or for cell modification.

These products are highly complex, and their functionality is impacted not only by their design, but also their manufacturing processes. Understanding and control of the manufacturing procedures is critical to achieve consistent outcomes, as is the control of the analytical procedures used to determine their purity and functionality.

Therefore, there is a requirement that control and scientific oversight is applied not only to the production of materials for toxicological and first in man studies, but also for the material generated for evaluation in drug discovery functions. This not only ensures that there is consistency in the quality of material used in pivotal drug discovery activities, but confidence in the study outputs and the decisions made.

The knowledge base generated from these studies supports the translation from discovery to clinical production and first in man studies, where there are defined regulatory requirements around vector production and the testing/release of material.

- The connectivity between discovery and clinical manufacturing

- Criticality of vector analytics and quality within discovery and clincial production

- The need for long term strategies linking discovery activities and clinical supplies

You have registered for this webinar

You might also like

A more perfect disease model – engineered iPSCs from innovation to discovery

Streamline disease modeling and therapeutic discovery with targeted viral vectors

Learn how to design a simplified, cost-effective LVV manufacturing workflow

A case study in faster, higher-quality pDNA manufacturing